HP Materials & Additive Manufacturing Expansion

The additive manufacturing industry continues to accelerate, and HP’s latest announcements at Formnext 2025 highlight just how quickly the landscape is evolving. HP introduced a set of new AM materials aimed at improving strength, surface quality, and production-scale reliability—key challenges for both prototyping and end-use manufacturing.

The company also unveiled updated workflow tools that simplify the process from design upload to finished part. These tools are focused on reducing operator time, minimizing setup errors, and enabling faster iteration cycles. For small businesses, engineering teams, or independent designers relying on rapid prototyping, these upgrades can directly translate to lower development costs and improved turnaround times.

HP’s direction reflects a broader trend in the industry: manufacturing teams are beginning to treat additive not just as a prototyping method, but as a legitimate production solution. With improved material performance and more predictable workflows, AM continues to shift from “experimental technology” to “day-to-day manufacturing asset.”

Full article: HP Inc. Drives Additive Manufacturing Adoption Through Portfolio Expansion & Material Innovations at Formnext 2025.

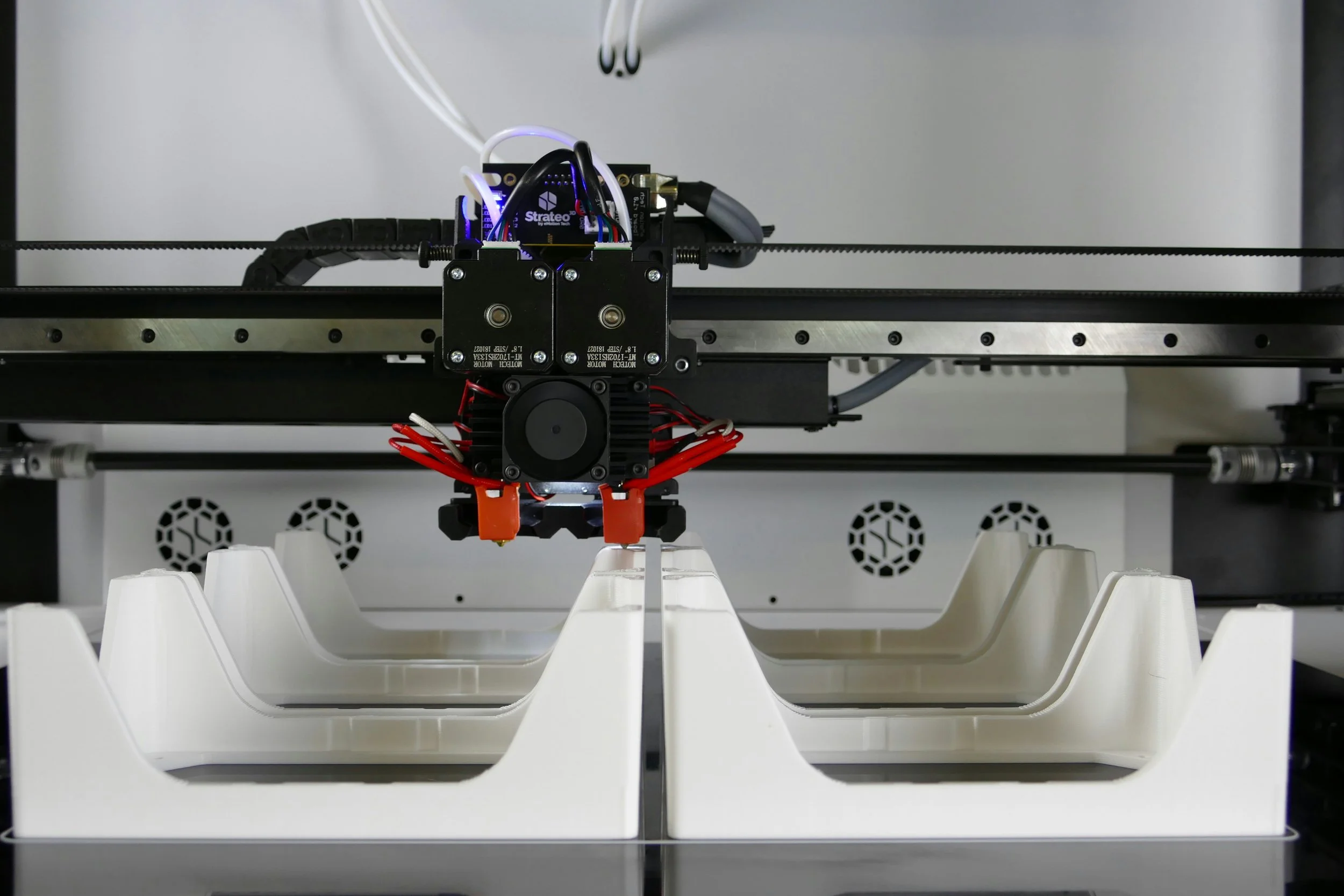

Photo by eMotion Tech on Unsplash