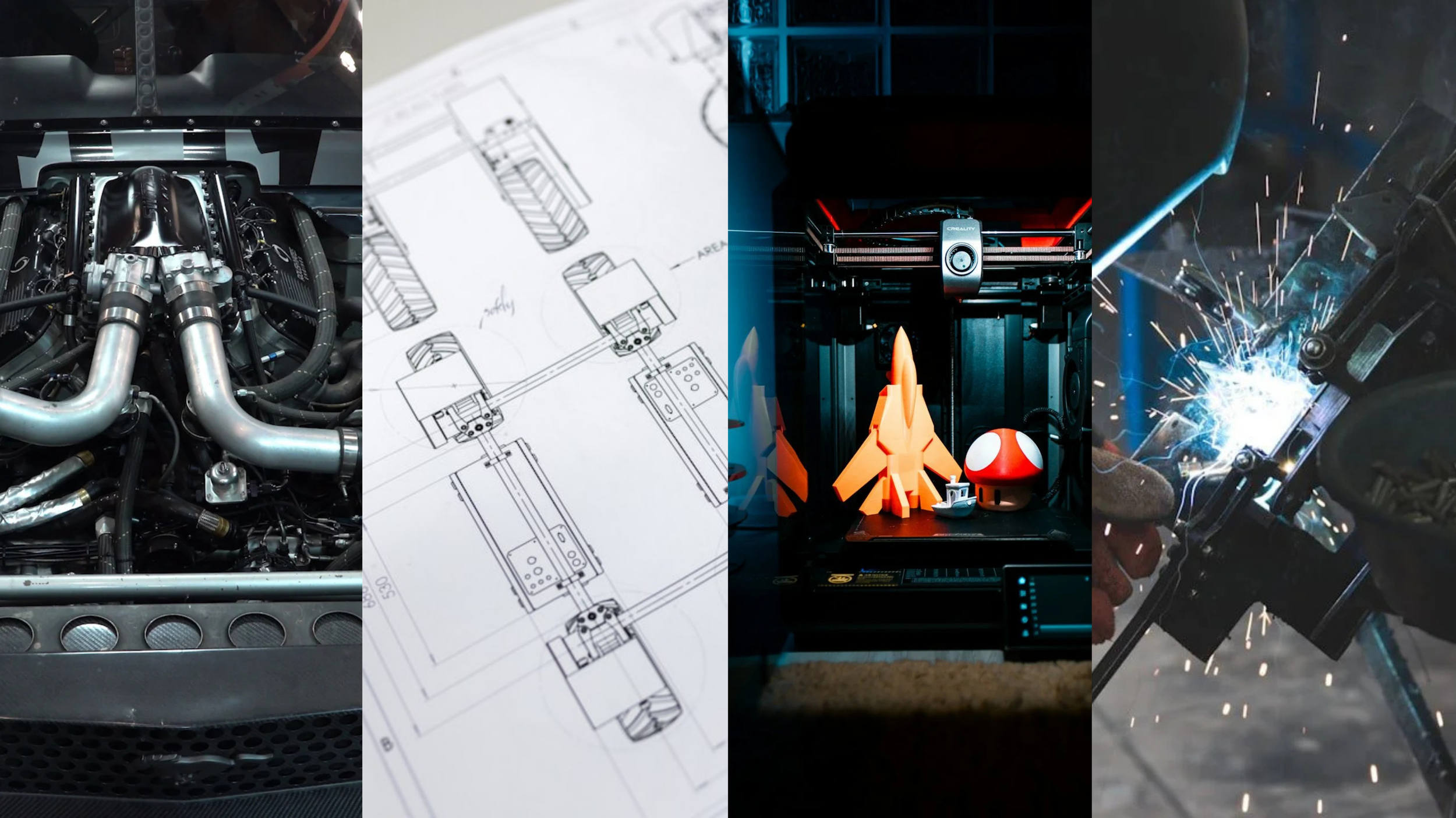

Welcome to Pacheco Solutions

Bringing Concepts to Creation

Services

-

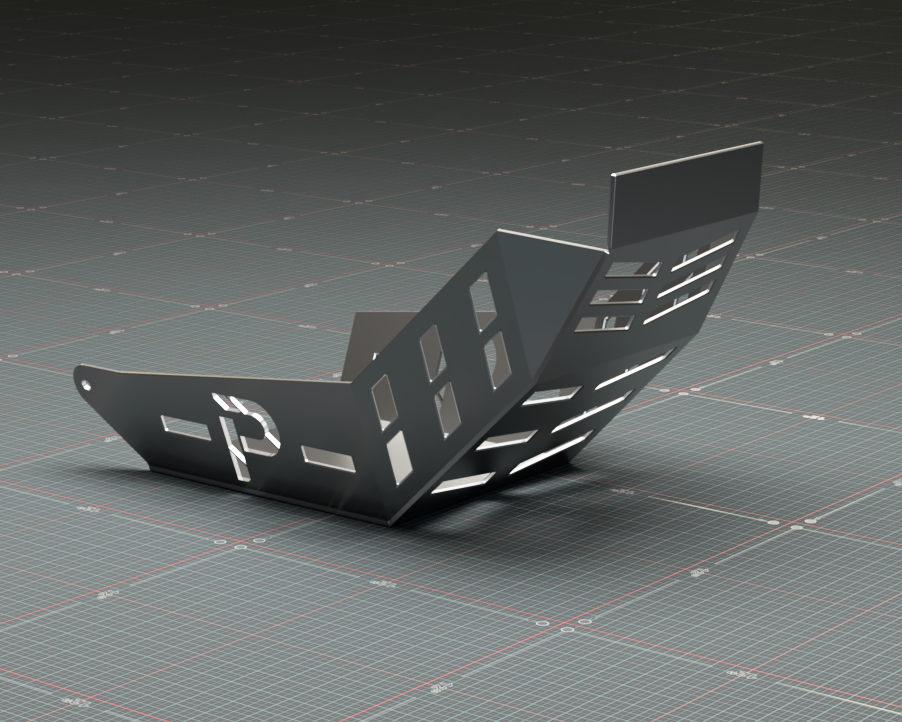

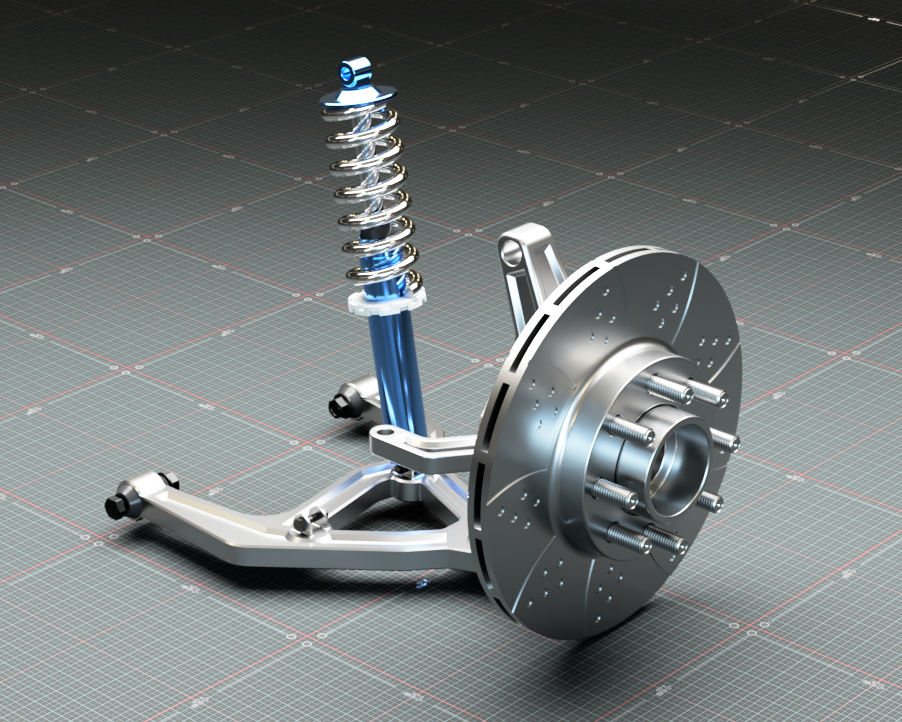

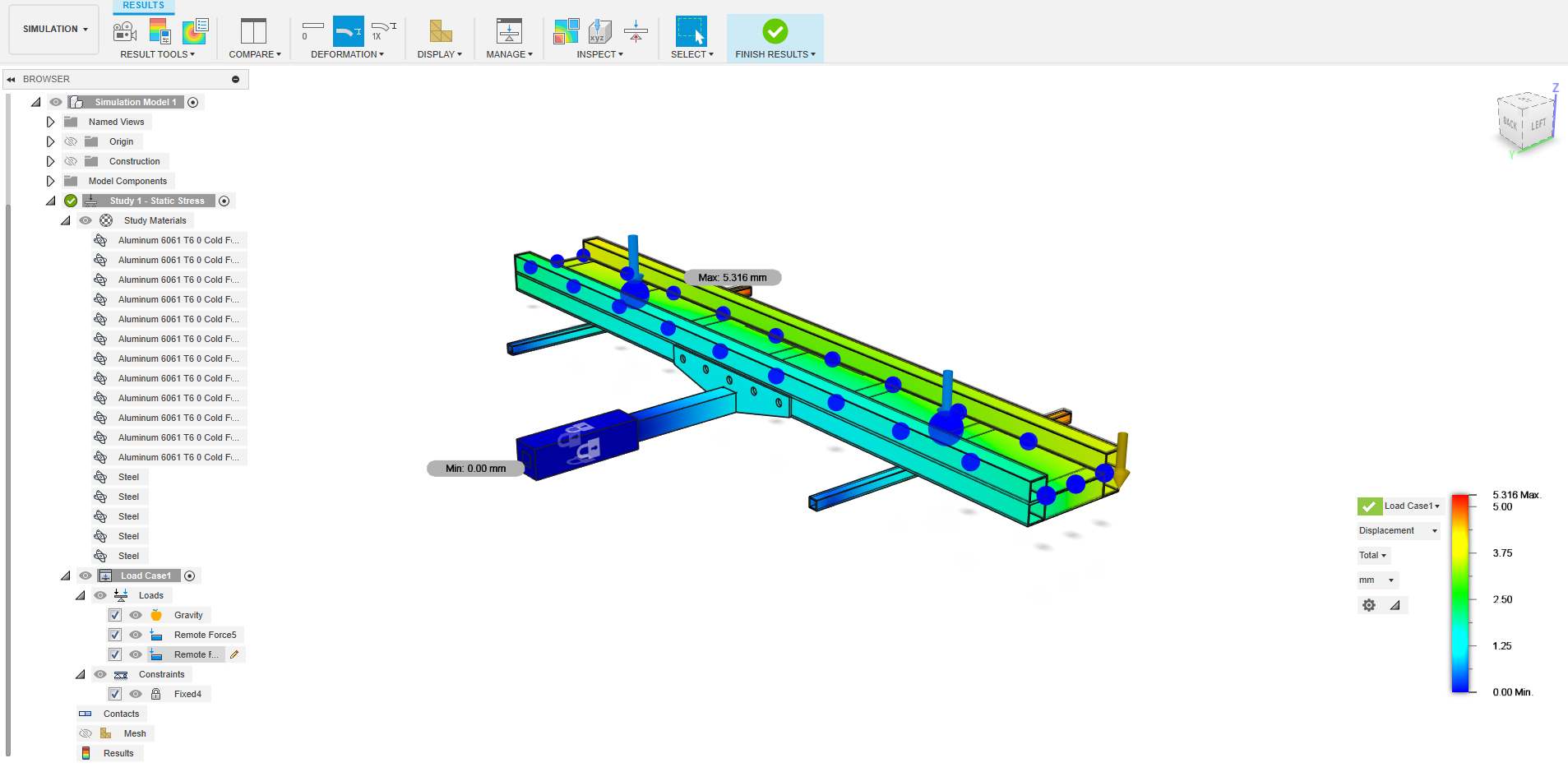

CAD Design

Transform ideas into precise 3D models, ready for prototyping or production. Simulation-Driven Results.

-

DFM Consulting

Optimize designs for manufacturability, reducing cost and complexity without sacrificing performance.

-

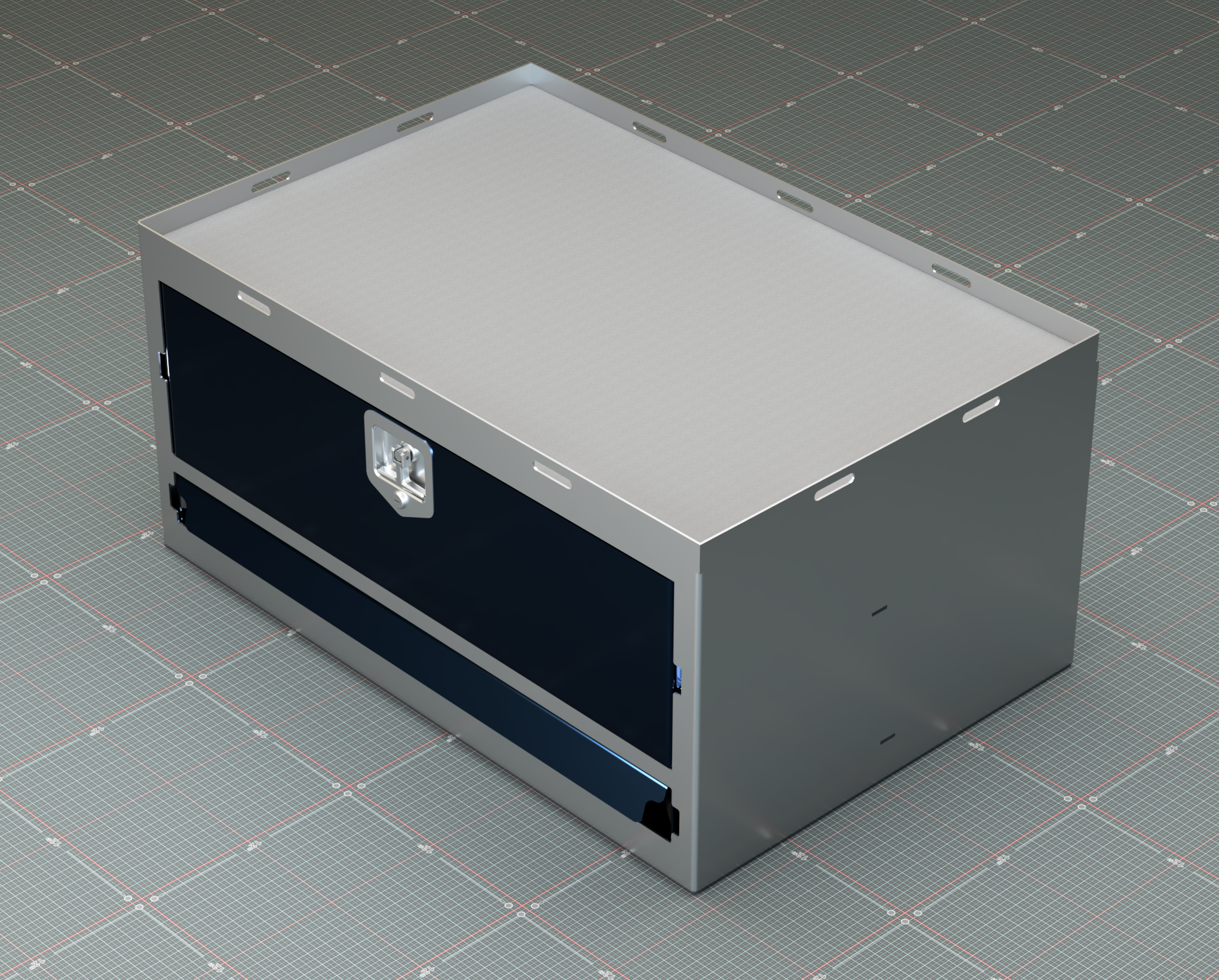

Fabrication

From prototypes to custom parts, we deliver functional, durable prototypes built to spec.

-

Technical Documentation

Clear, professional drawings and manuals that ensure smooth communication from design to production.

Testimonials

-

"What a giant step forward! I could not be happier to see an concept come into focus. Thank you for caring enough to truly help me get this idea from a concept to a reality. I absolutely love your attention to detail and the cleanliness of your drawings."

- Messer Metal Fabrication

-

"Jacob was extremely professional and timely with fast and productive communication. Highly recommend for future projects."

- Modular Fisherman

-

"Very responsive and friendly, high quality work, and finished wayyyyyy ahead of schedule too!"

- Steve Nabi - Sole Proprietor

Notable Projects

Clients We Serve

-

Sea To Sky Welding

-

RJ Manaufacturing

-

Azure Digital

-

Messer Metal Fabrication

-

AMROK

-

UnlimitedIRL

Company News

Messer Metal Fabrication is beginning test fitment of the portable Bronco workstations. Perfect for on site, off road, rugged use. Designed and manufactured to put quality first and echo, “American Made”. Visit Messer Metal Fabrication to learn more.

Our 3D printing toolset has been expanded with the addition of the P1S AMS Combo kit. Allowing us to offer multi-color printing and larger print sizes. Feel free to reach out for more information.

Finally, as contracts close, we welcome new customers to reach out. Offering quality designs and a long term partner to build reality. From simple sketches to full blown manufacturing packages, we offer quality and top end customer service. Honoring the craft. Elevating the design. Built on trust, delivered with pride